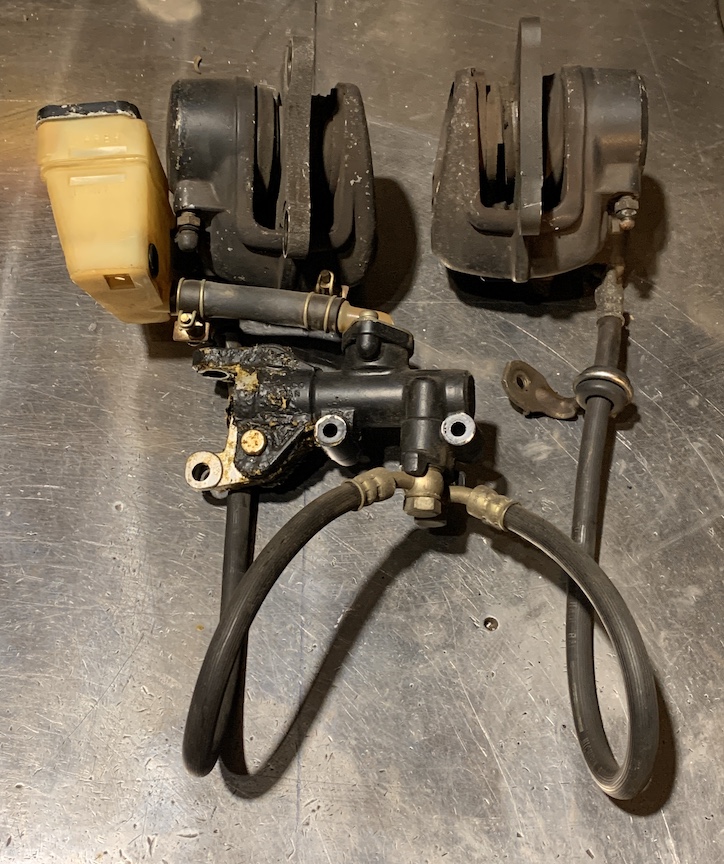

Holidays are over and time to get back on this project. More disassembly indicated more problems. I started with the brakes since corrosion and brake fluid was evident where it shouldn't be. The early Z1Rs had a cable operated front master cylinder with a 5/8 piston. Rebuild kits are available but not the master cylinder. The few I have found are corroded as mine is. Later models had the master cylinder on the handlebars.

- Brakes front.jpg (282.71 KiB) Viewed 11090 times

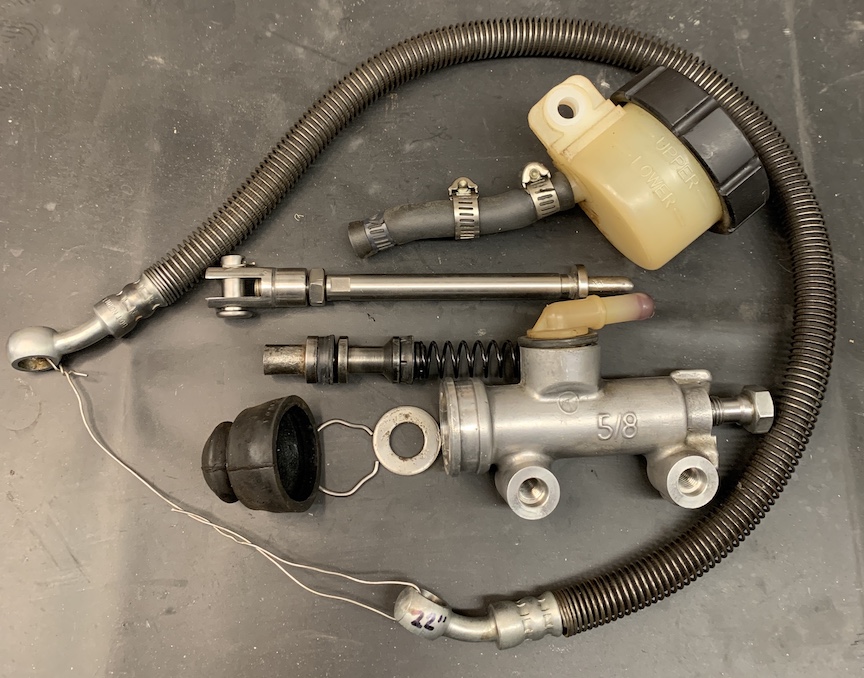

I had one option and that was to bore, sleeve and hone it, so I did. One down, one to go and it's another unusual version.

- Master Cyl re-sleeve.jpg (233.77 KiB) Viewed 11090 times

The early Z1Rs had a master cylinder with a remote reservoir. The bore is the same as the front master cylinder but the rebuild kit is different. So, the next step it to sleeve as the bore is also pitted.

- Brakes rear.jpg (227.18 KiB) Viewed 11090 times